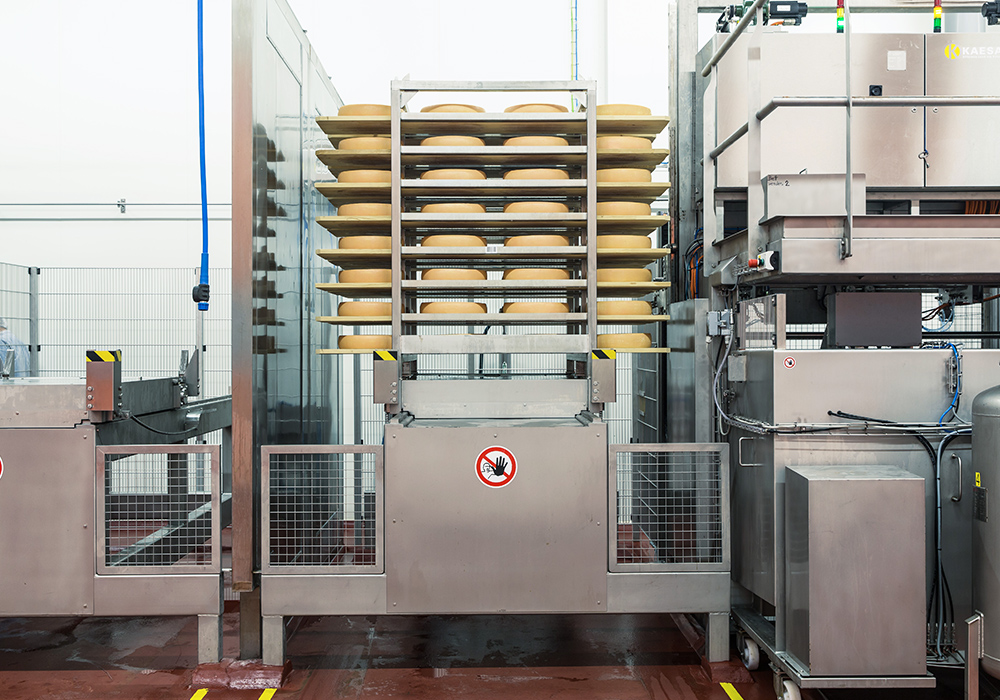

The stationary cheese care robot

KAESARO S – is used stationary, working completely automatically with a high machine performance. The transport of the maturation racks out of the cheese cellar to the KAESARO S and back can be performed manually or automatically.

CAD – animation

with stretched mast

Stationary operation

KAESARO S works fully automatically in stationary operation. If required, cheeses are stored directly after the salt bath. The transport racks are moved manually or automatically via driverless transport systems.

Adapted to workflow

The planning of a KAESARO system is very individual – tailored to the operating processes. In addition, the KAESARO S lubrication robot can be enhanced via various modules.

High-performance

The KAESARO S processes up to 200 boards per hour.